Published: June 20, 2023

Updated: March 21, 2025

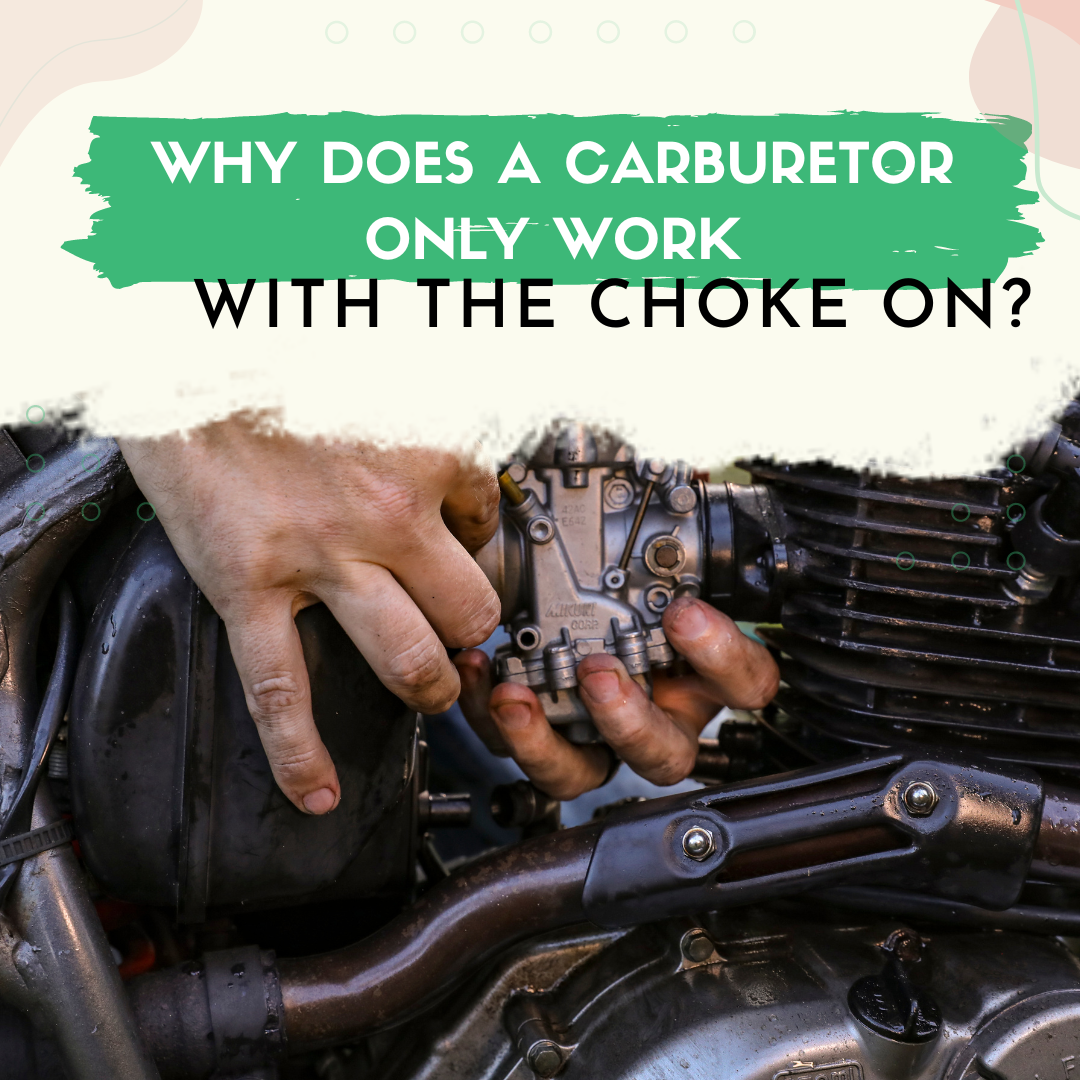

Why Does a Carburetor Only Work With the Choke On?

Ever puzzled over why your carburetor only runs with the choke on? You’re not alone—it’s a head-scratcher for many riders.  Let’s dive into the fix.

Let’s dive into the fix.

The Quick Answer

If your carburetor only works with the choke on—even after warming up—it’s a sign the fuel-air mix is off. Culprits? Bad adjustments, a dirty carb, or issues like a busted gasket or air intake.

Carburetor 101

A carburetor mixes air and fuel for your engine—think of it as the engine’s lungs. Key parts:

- Choke: Limits air for cold starts, enriching the mix.

- Jets: Meter fuel flow.

- Venturi: Speeds up air to pull in fuel.

Why Choke-Only?

Normally, the choke helps cold starts, then opens as the engine warms. If it stalls without the choke, the mix is too lean—too much air, not enough fuel. Here’s why:

- Misadjusted Mix: Tweak the mixture screws for balance. See backfire fixes.

- Dirty Carb: Gunk blocks fuel flow—clean it out. Carb cleaning guide.

- Gasket Issues: A torn gasket lets in extra air—replace it.

- Air Intake/Vacuum Leaks: Cracked boots or lines mess up the mix—check and fix.

- Clogged Jets: Debris starves fuel—blast it clear.

Fix It Fast

Troubleshooting Steps

| Issue | Fix |

|---|---|

| Lean Mix | Adjust mixture screws |

| Dirty Carb | Clean with carb spray |

| Leaks | Replace gasket/boot |

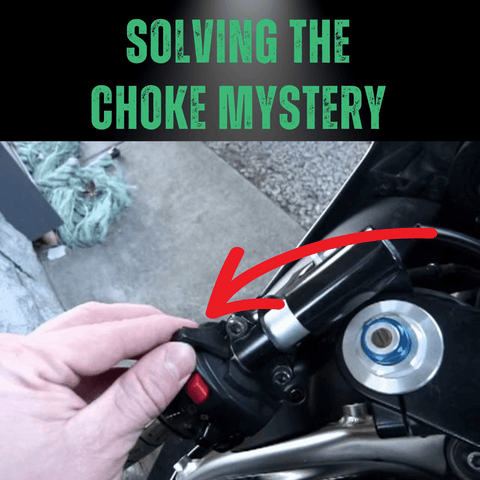

Pro Tip: Cool the engine first—safety matters. Watch this:

Keep It Running

- Clean Often: Spray jets yearly.

- Fresh Fuel: Use stabilizer for storage.

- Check Gears: Inspect gaskets and lines regularly.

Wrap-Up

A choke-only carb signals trouble—fix it with adjustments, cleaning, or part swaps. Get it right, and your ride’s back to smooth sailing. Need kids’ bikes? Check our collection!

Frequently Asked Questions

Can I run my bike with the choke always on?

Not smart—it wastes fuel, fouls plugs, and risks damage. Fix the root issue.

How often should I clean my carburetor?

Once a year—or sooner if it’s gunked up. Check your manual.

What’s a sign my carb needs tuning?

Rough idle, hard starts, or black exhaust smoke—time to tweak it.

Need More Bike Tips? 🏍️

Love this guide? Roll over to RiiRoo.com or hit our Live Chat!

Share:

Go-Karting vs. Car Driving: How Go-Karting Skills Boost Safe Driving in 2025

Does Go Karting Make You A Better Driver?